Construction of the cones.

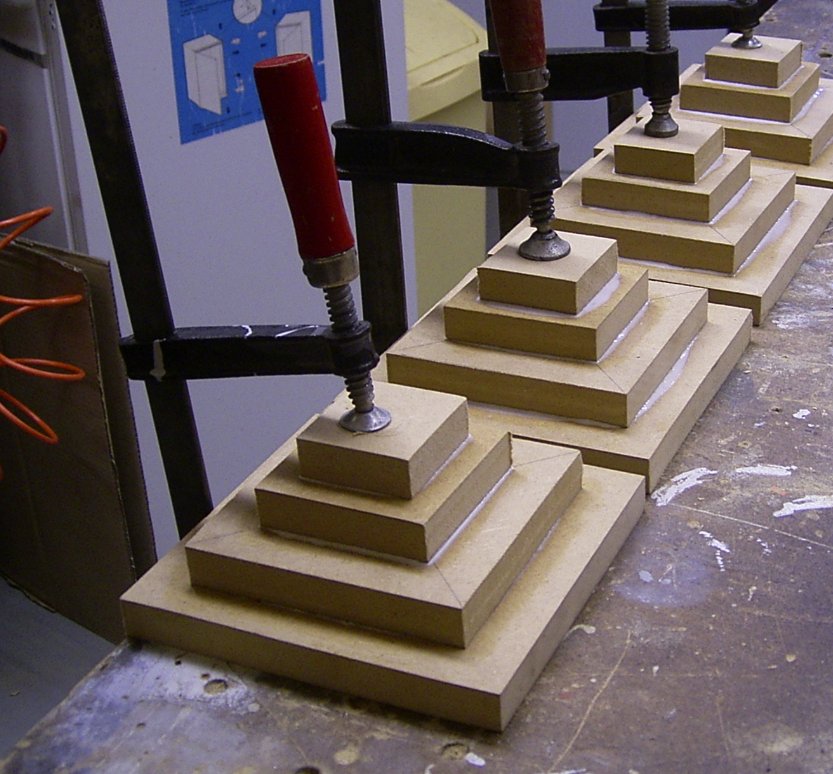

The 4 half-cones are each milled out of a pile of MDF squares, glued together.

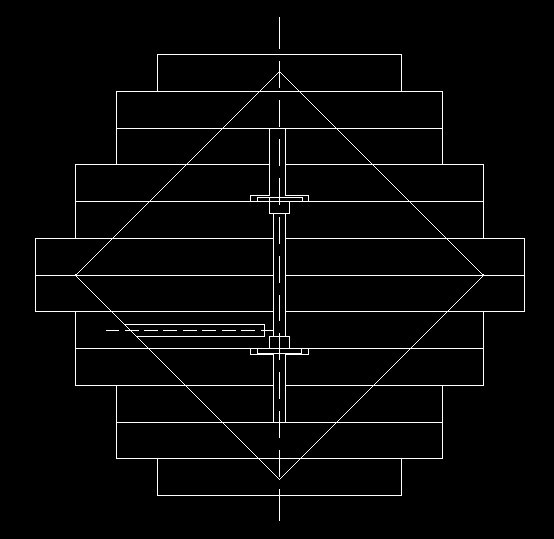

Below a section of two half-cones together.

The half-cones are held together by a piece of M6 threaded rod and two ringnuts.

Construction drawing.

Note the ringnuts and the channel for the M6 treaded rod which keeps two half-cones together, and horizontally one hole for mounting the cones between the loudspeakers with aluminum rods. There should be 3 such holes, angled 108 - 144 - 108 degrees in the horizontal plane.

The rods shoud be inserted spring-loaded, otherwise the final mounting will be quite tricky.

The pictures below were made during the construction of a smaller version in 2004.

Drilling a chamber for the ringnut.

Glueing the square plates together.

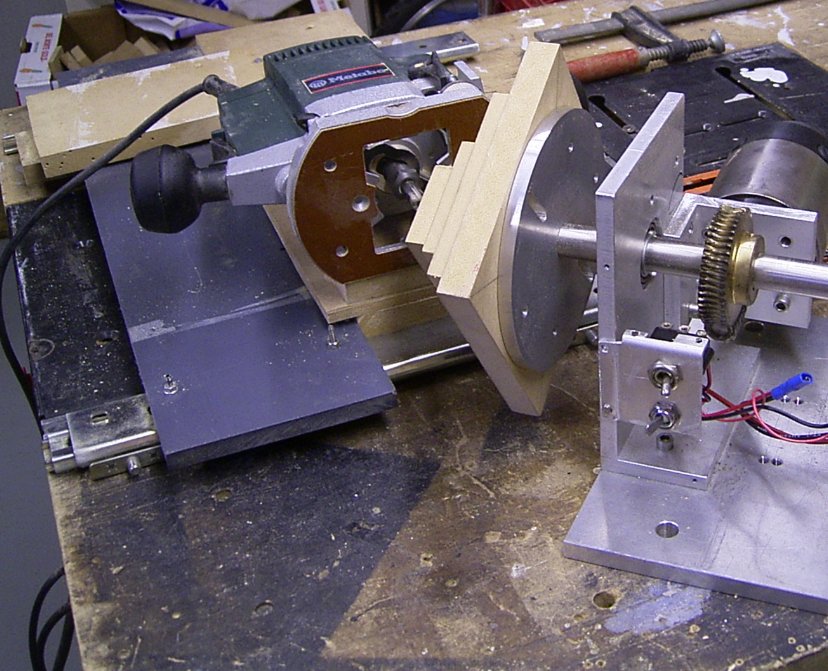

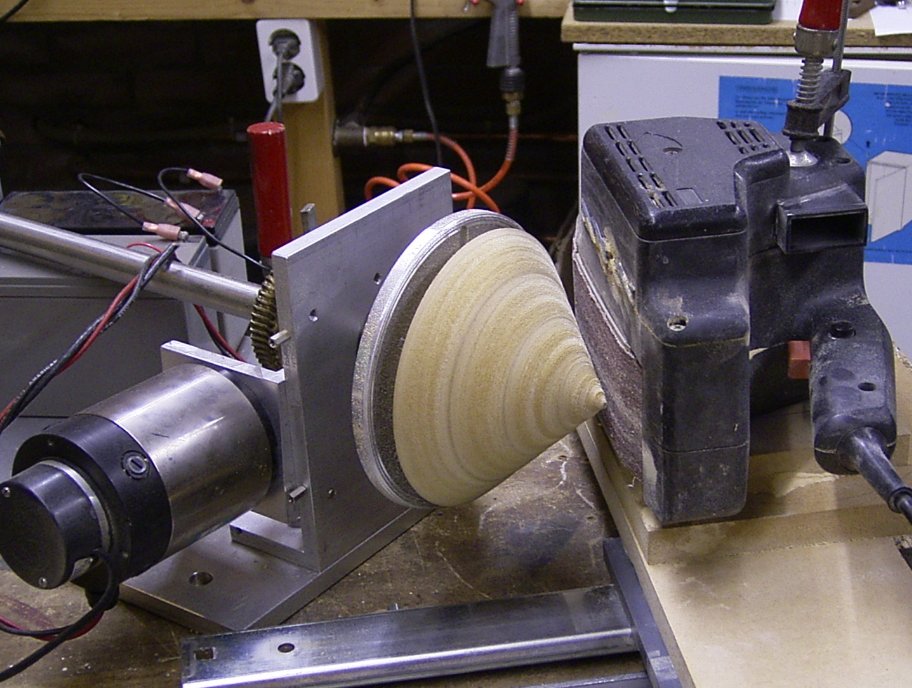

For the milling I happened to have a motorized rotor on which the glued pieces were mounted.

The milling machine was mounted on a construction with linear ball bearings from some drawer cabinet.

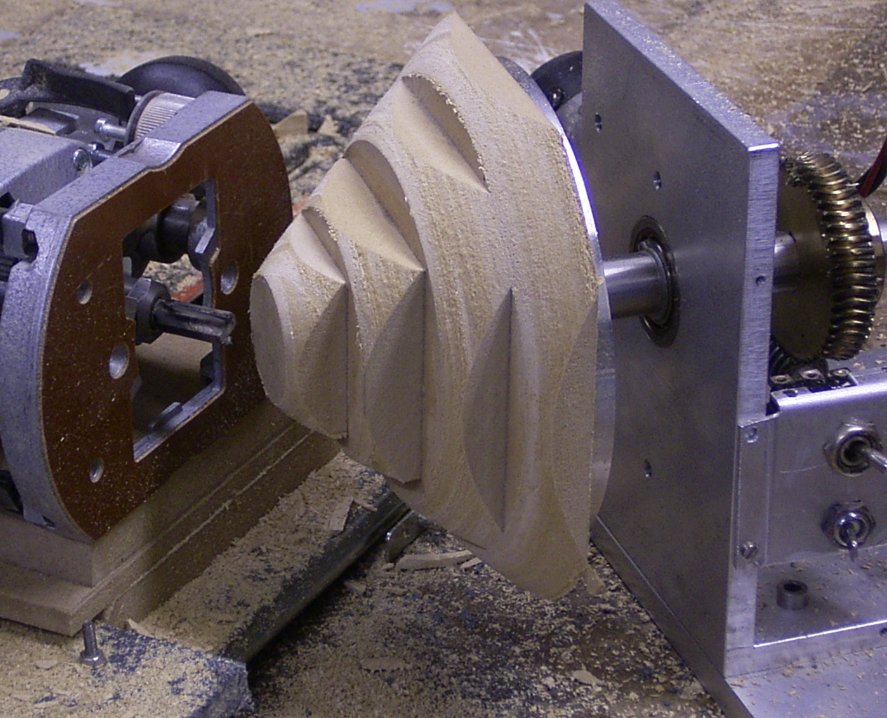

Cone milling halfway.

Sanding. Be sure that all cones will have the same diameter.

The halfway finished cones. After this, fine-sanding, varnishing and drying was applied repeatedly.

The tip can be slightly rounded off, because it is prone to be damaged.

It does look a bit like Jupiter isn't it?